Multi-Circuits Din Rail Energy Meter

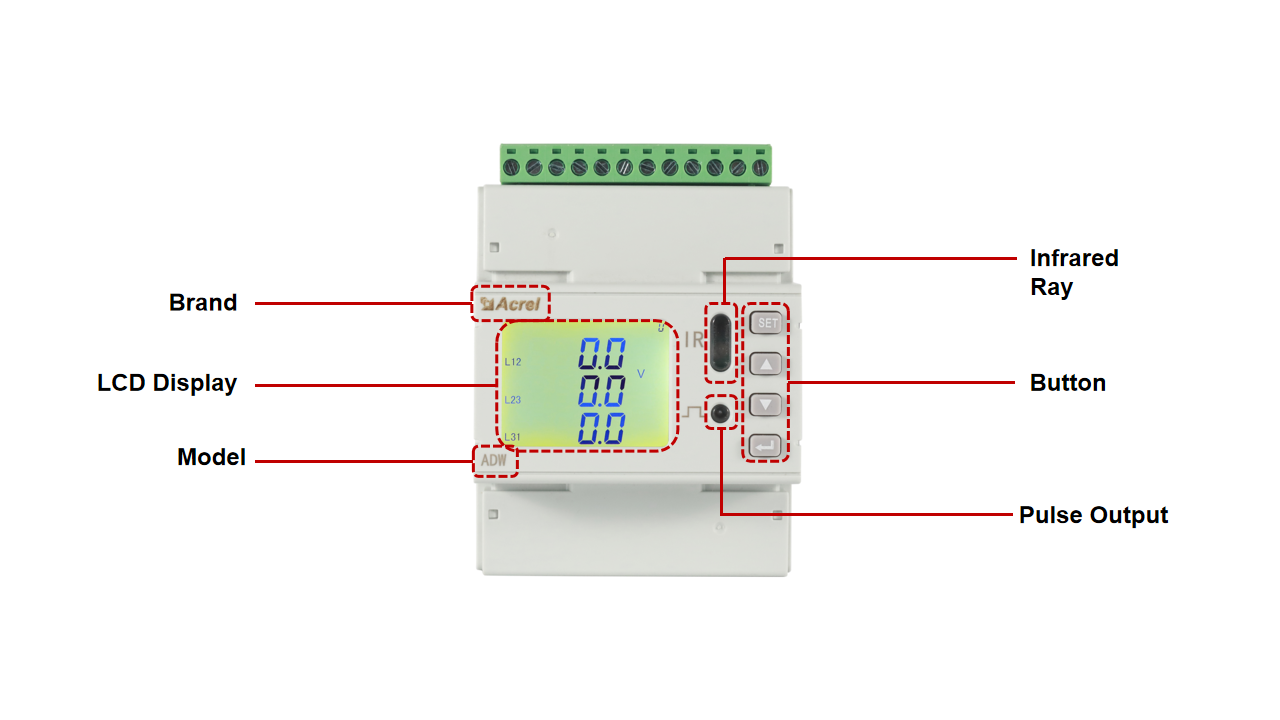

ADW210

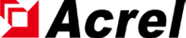

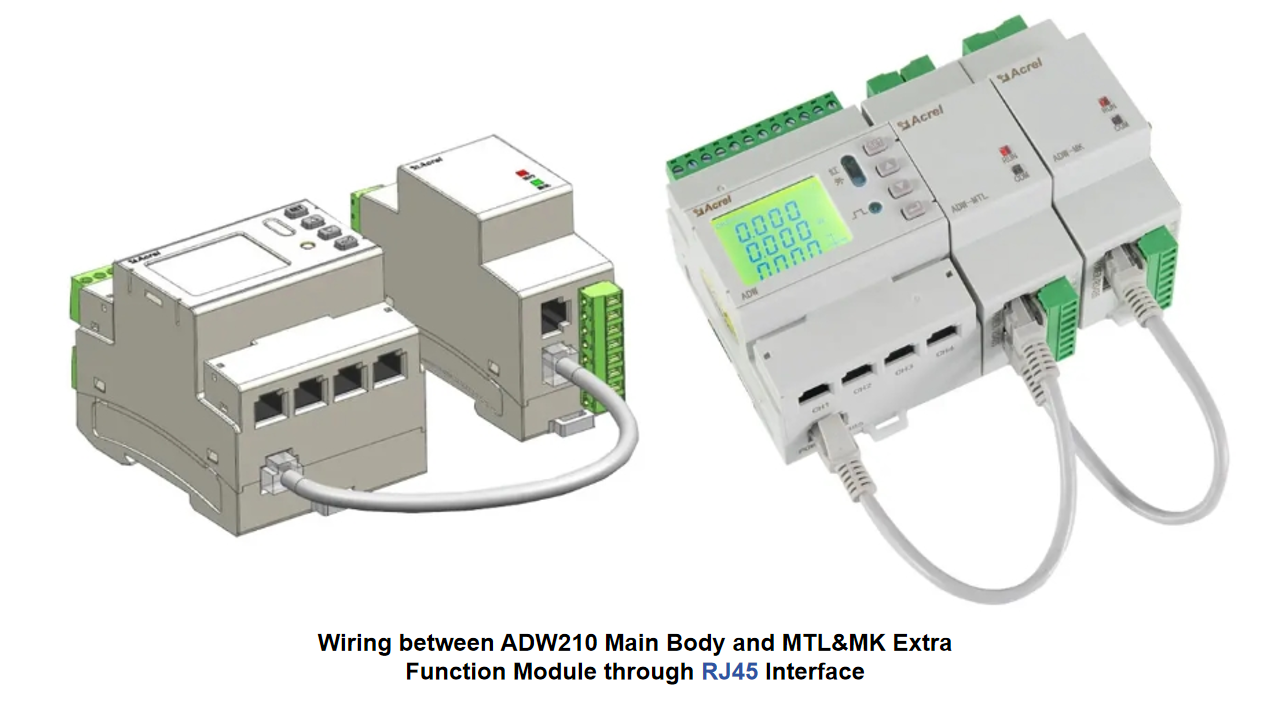

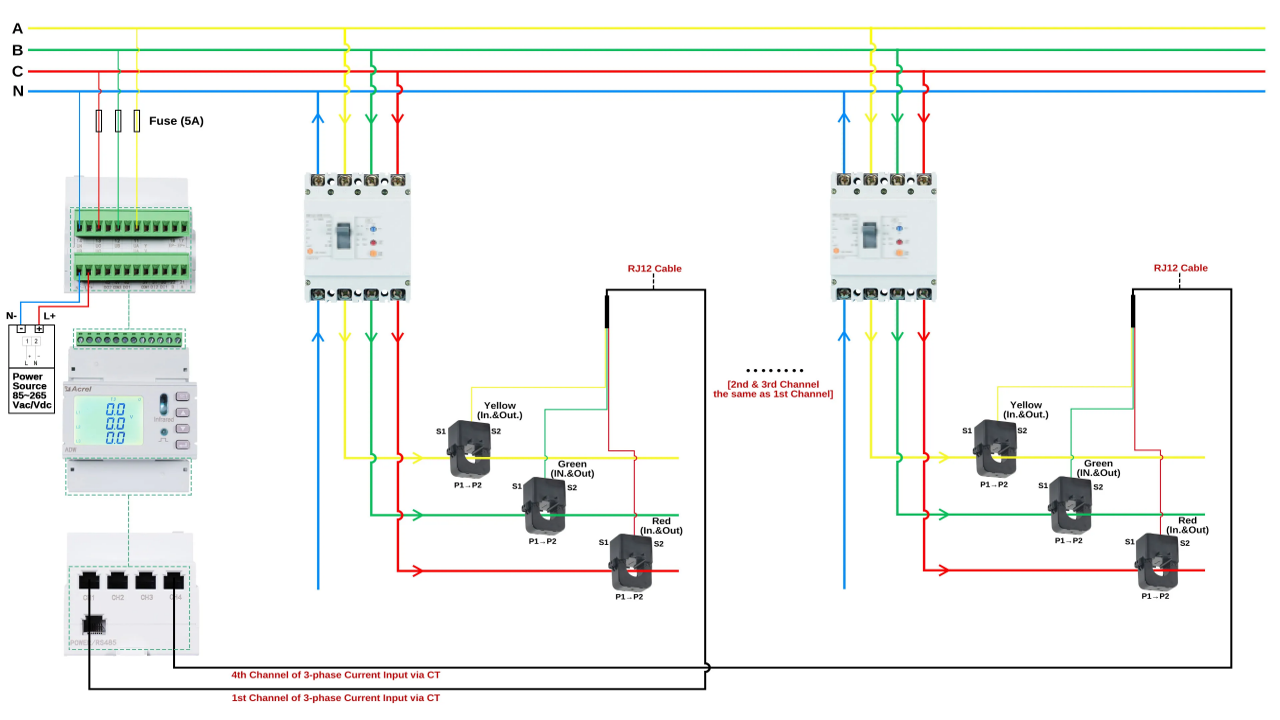

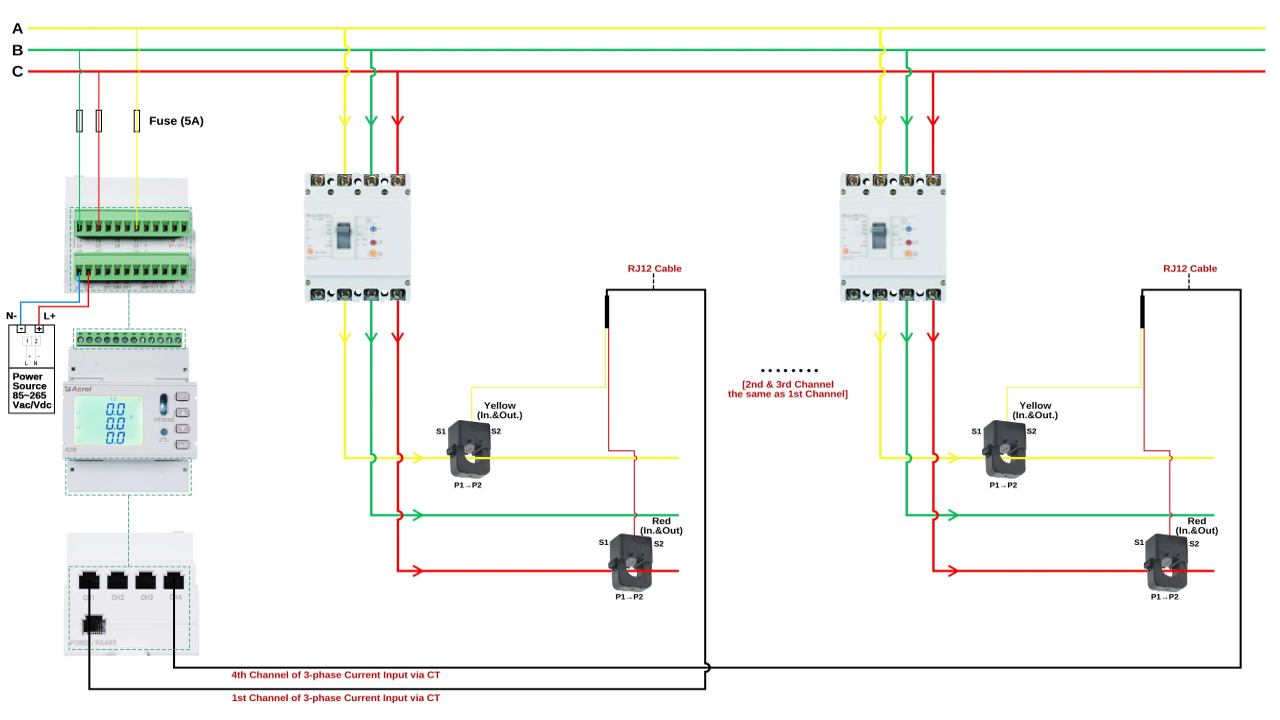

Max 4 Loops Three Phase(12 Loops Single Phase) Energy Metering With RJ12 Terminal CTs

DESCRIPTION

|

The product is a rail-type multi-loop power meter, including MCU module and power module, a metering module, a current module, and a voltage input module.It supports real-time monitoring of multi-circuit current, voltage, power, energy and other parameters, and is suitable for refined energy consumption management of branch circuits. It is equipped with RJ12 interface current transformers, which is easy to install and suitable for compact distribution box environments. Typical application scenarios include: 1.commercial buildings: branch circuit energy consumption monitoring, refined control of loads such as air conditioning and lighting; 2.industrial power distribution: energy consumption monitoring and fault warning of production lines and motor circuits; 3.photovoltaic systems: distributed photovoltaic power generation metering, two-way power statistics; 4.intelligent operation and maintenance: docking with energy management platforms (such as Acrel-EMS) to achieve remote meter reading and energy efficiency optimization. |

|

|

|

|

|

|

Installation: Easy Installation |

Service: 24 Hour |

|

|

|

|

|

Certificate: CE/RoHS |

Quality: Quality Assurance |

|

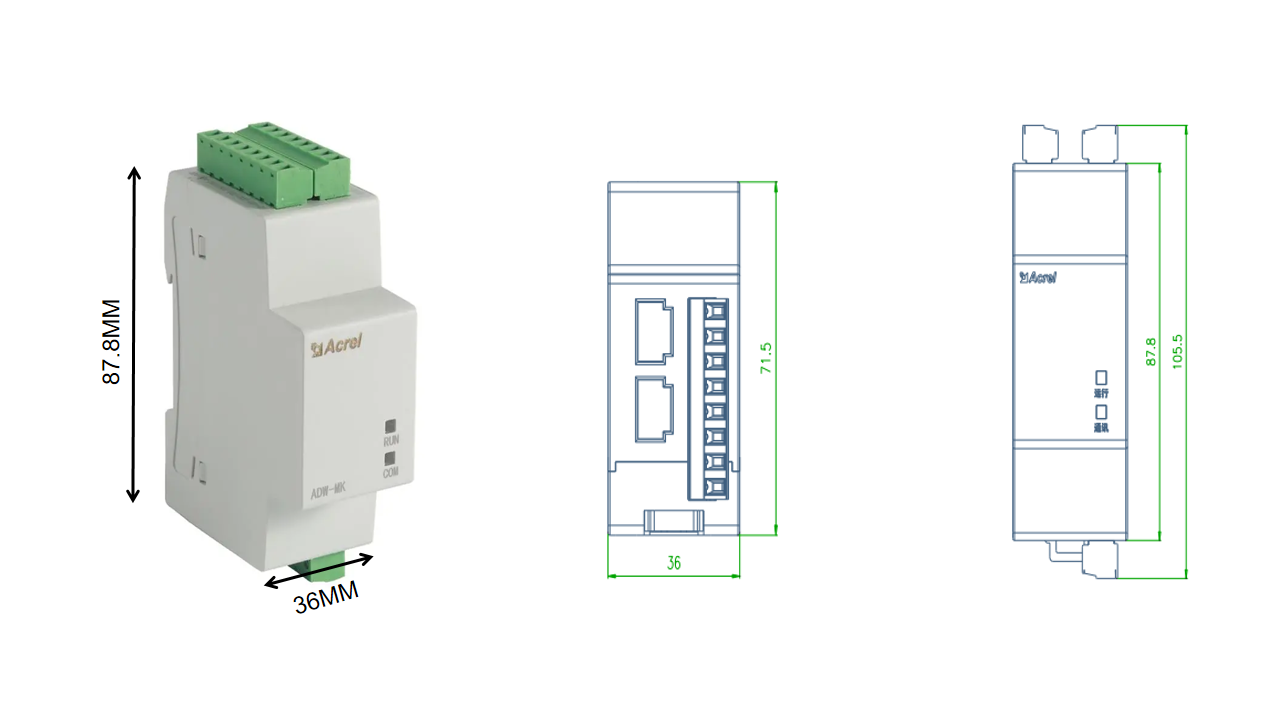

Interface Descriptions

这里是占位文字

Related Products

Messages

Filling in your phone and email information will help us to contact you in a timely manner and resolve your issue as soon as possible.

Multi-Circuits Din Rail Energy Meter

Product Summary:

Used for connection between pipe ends; Also useful is a flange on the inlet and outlet of the equipment, used for connecting between two devices, such as a gearbox flange. Flange connection or flange joint refers to a detachable connection consisting of flanges, gaskets, and bolts connected to each other as a combination sealing structure. Pipeline flange refers to the flange used for piping in pipeline devices, and when used on equipment, it refers to the inlet and outlet flanges of the equipment. There are holes on the flange, and bolts make the two flanges tightly connected. Seal the flanges with gaskets.

Classification:Butt welded pipe fittings

Keywords: Butt welded pipe parts

产品详细

There are GB series (national standard), JB series (mechanical department), HG series (chemical department), ASME B16.5 (American standard), BS4504 (British standard), DIN (German standard), JIS (Japanese standard).

Advantages:

The on-site installation is more convenient, and the process of welding seam rubbing can be omitted

Disadvantages:

The neck height of the flat welded flange with a neck is relatively low, which improves the stiffness and load-bearing capacity of the flange. Compared with butt welded flanges, the welding workload is large, the consumption of welding rods is high, and it cannot withstand high temperature and pressure, repeated bending, and temperature fluctuations.

The connection is not easily deformed, with good sealing effect, and is widely used. It is suitable for pipelines with significant temperature or pressure fluctuations, as well as pipelines with high, high, and low temperatures. It is also used for transporting expensive media, flammable and explosive media, and toxic gases